TPE 251

Description

The pad printing machine TPE 251 with electro-pneumatic drive and equipment for the sealed inking system, offers versatile application possibilities at a convincing price- performance ratio. Thanks to features such as an easy to understand compact PLC control unit and a quick-change system for inks and plates, the TPE 251 meets all requirements of a modern, user-friendly pad printing machine. The practical ink cup holder with bayonet lock or the optional electric rotating cup cylinder are available for cup fastening. As a pad printing machine in the medium size range, the TPE 251 proves to be a practical allrounder that is available with many extras e.g. the automatic pad cleaning device.

TPM 101

Description

Compact and user-friendly, the electromechanical state of the art TPM 101 Pad Printing Machine is well-equipped to meet the requirements of today's market. The highest demands for cycle speed and print accuracy are fulfilled: the single colour printing machine is exceptionally well-suited for integration into automated systems with a print capacity of 1500 to 4000 prints per hour. With plate cooling and temperature compensation, new special technical functions are available as an option, which help to increase process stability and ensure a consistently high-precision print result.

TPX 250

Description

The TPX 250 pad printing machine with an open inking system is driven electropneumatically. The compact printing machine shows its advantages especially at manual workstations. Highest print accuracy and repeatability characterise the TPX 250 as a universally suitable pad printing machine for a variety of applications. The TPX 250 can be combined with many peripheral devices, e.g. the automatic thinner injection, with rotary or swing table, pad sliding device, etc.

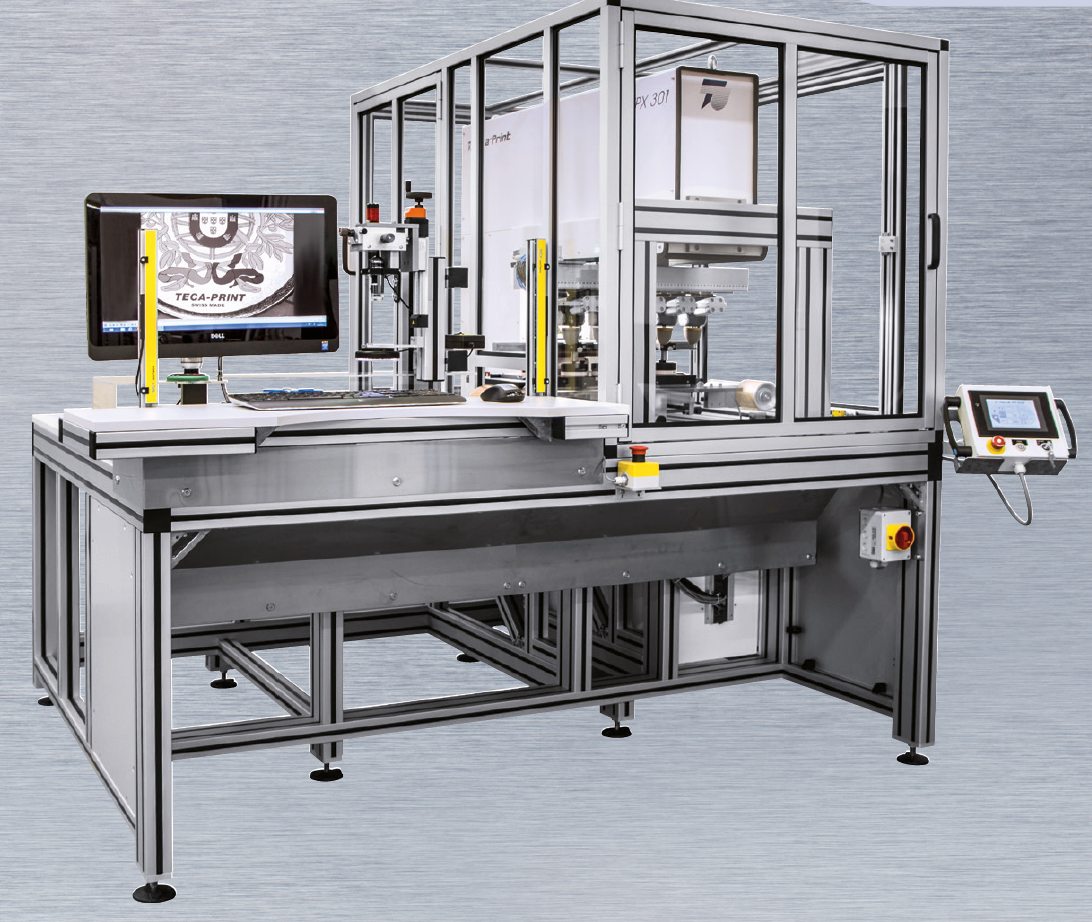

TPX 301

Description

Printing a coin is an extremely complex and challenging task. Even the smallest and most detailed photoprints must appear rich in colour and perfectly aligned. The Teca-Print Mint Workstation is specially designed and built to meet the needs of the mint industry. The electromechanical machine with an integrated camera system fulfils the highest expectations and thanks to the monitoring of the print result, misprints on the high-quality print products are immediately detected and minimised accordingly.