SC-AII Series

Description

Fully Automatic Swing Cylinder Screen Printing Machine

SC-AII models are capable of printing on various soft and semi-rigid substrates such as paper, plastic sheet, film and metallic sheet, ranging in thickness from 0.1 to 0.8 mm.

Hairline registration is guaranteed at print speeds of 1,500-2,500 (SC-142AII 1,000~2,000) sheets per hour, which is three of four times the production rate of conventional flat bed presses. SC-AII presses can be used for POS, posters, stickers, self adhesives, decals, membranes and other applications.

Specification

| MODEL | SC72AII | SC102AII | SC112AII | SC142AII |

|---|---|---|---|---|

| Max. print size (mm) | 720 x 520 | 1020 x 700 | 1130 x 800 | 1400 x 995 |

| Printing speed (IPH) | 1000 ~ 3600 | 900 ~ 3300 | 900 ~ 3300 | 800 ~ 2000 |

MS A Series

Description

Fully Automatic Stop Cylinder Screen Printing Machine

Designed to meet the ever increasing demands in the field of industrial and commercial screen printing, Sakurai is manufacturing 2 sizes of fully automatic stop cylinder screen press covering B2 to B1 sizes. Can be used commercial printing such as transcription & textile & name plate & security printing, and also industrial printing.

Specification

| MODEL | MS-80AII | MS-102AX |

|---|---|---|

| Print Size | 770 x 520 mm | 1050 x 730 mm |

| Speed | 400 ~ 3600 IPH |

800 ~ 4000 IPH |

| Thickness | 0.05 ~ 0.8 mm | 0.075 ~ 0.8 mm |

LQM EVOLUTION SERIES

Description

LQM Evolution Series

Sakurai LQM-76/105 inline hot foiler gives the best possible luxury foiling results at a minimum cost with minimum waste. Fully Automated and extremely precise, this foiling system uses screen-printed varnish to adhere the foil. This process enables to achieve a wide variety of ink film thicknesses, which can produce 3D (raised) print, structured varnish effects. Special effects like glitter, glow in the dark, different textured finishes with tactile surfaces or highly saturated pantone colors.

Specification

| Model | LQM-76 EVOLUTION | LQM-105 EVOLUTION |

|---|---|---|

| Substrate loading size |

Min. 350 x 270 mm Max. 760 x 520 mm |

Min. 560 x 350 mm Max. 1050 x 750mm |

| Substrate thickness | 0.14 - 0.47 mm |

0.14 - 0.47 mm |

|

Work mode |

a) Partial foil mode b) Continuous mode c) Bypass mode |

a) Partial foil mode b) Continuous mode c) Bypass mode |

| Foiling speed |

max. 30 meter/min. (55 m/min. in Bypass mode) |

max. 30 meter/min. (55 m/min. in Bypass mode) |

MF-80VII

Description

Fully automatic Flat Bed Screen Printing Machine

Maestro MF-80VII is a fully automatic flat bed screen printing press that combines automatic front pick up feeder and flatbed printing unit, and can be used such as automotive instruments, textiles, nameplates, and membrane printing. The CCD cameras (optional feature) reads the registered mark on the printed substrate and the suction table moves for sheet alignment.

Specification

| MODEL | MF-80VII |

|---|---|

| Print Size | 800 x 600 mm |

| Speed | 1000 IPH |

| Thickness | 0.1 ~ 3 mm |

MSDR SERIES

Description

Maestro Direct Servo Drive Roll To Roll Cylinder Screen Press

The MSDR copes with 25um thick film utilized for thin electronic parts like MLCC. Two models are available by material width: MSDR-60 (max. 600mm) and MSDR-30 (max. 300mm). High productivity is obtained by cylinder type screen printing. CCD camera aligns the substrate accurately. Heavy ink deposition can be obtained on variable substrate. MSDR series is best suited for Label printing and printed electronics industry.

Specification

| MODEL | MSDR-30 | MSDR-60 |

|---|---|---|

| Max. Print size (mm) | 250 x 250 | 550 x 550 |

| Speed (sec./shot) | 3 | 3 |

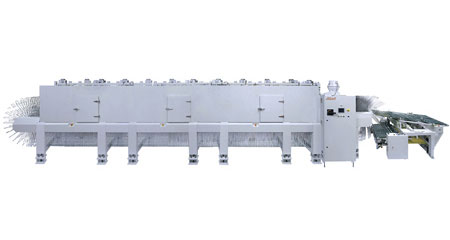

Wicket Dryer MS-80LH

Description

The advantage of wicket leaf dryer is to dry printing substrates for a longer period of time, so this dryer effects to use thermal sensitive materials which are easily deformed by high temperature air or IR waves. Each sheet/substrate is retrieved by an individual wicket leaf and dried slowly.

Stacker SST series

Description

This is an automatic stacker for wicket dryer. Individual drive system of the upper and lower belts allow smooth and stable movement of the delivered substrates. SST Side Stacker makes it easier to remove the piled substrates by sliding out the pile board from the operation or drive side without stopping the complete line.

Specification

| MODEL | SST-80 | SST-102 |

|---|---|---|

| Max. stock size (mm) | 800 x 550 | 1050 x 750 |

| Capability (Sheet/hour) | 3000 | 3000 |

| Max. loading capacity (kg) | 150 | 150 |

MS-102INS

Description

Fully automatic printed sheet inspection system

Renovation of Sakurai Inspection System to fasten processing speed up to 4,500 sheets/hour, and high pile specifications. By using a main body of MS series, register device and vacuum cylinder, high accuracy sheet feeding is realized. Products capable of printing in various thickness ranging from 0.1 to 0.4 mm. Hairline registration is guatanteed at print speeds of 2000 - 4000 sheets per hour with camera resolution of 0.13 X 0.13 mm.

MS-110DDS

Description

Fully automatic high precision direct servo drive stop cylinder screen printing machine

Direct servo drive mechanism has applied for major drive part of the press including the printing cylinder drive > No gears backlash is expected. Squeegee / Doctor blade are also controlled by servo motor drive, so setting of Squeegee / Flood coater pleasure and print stroke / clearance gap can be done from touch panel. Numerical job control can be applied. CCD camera checks register marks for alignment for higher accurate printing, it can be used for precision industrial printing. Cylinder vacume hole size 0.5mm which realizes very thinner film printing with quality